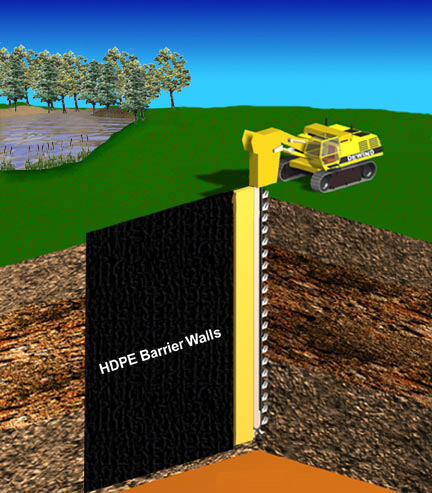

DeWind Trenchers can install rolls of HDPE barrier wall underground, under the water table in a single pass. DeWind’s custom designed poly installation attachment allows for the continuous installation of rolls of liner material to be easily installed in non-consolidated soils with high water tables. Poly walls can be installed on contaminated site without the need to excavate open trenches or install expensive dewatering systems that require discharge water management or treatment.

The HDPE Barrier wall attachment holds one full roll of 30, 40, or 60 mil material 22 foot long. After the trencher starts and gets the boom and delivery box into the vertical position the HDPE liner material is held in place. As the trencher advances backwards the liner is pulled off the roll and pulled into the newly cut trench where the native soils cave in on poly wall material locking it in place. When the roll runs out, another is dropped into the box and a vertical fuser welds the two ends of the rolls together creating a leak free seal.

Thousands of feet of wall can be installed in a day. Although Soil/Bentonite walls create the same impermeable wall as the HDPE poly material for half the cost, there are project sites that have certain contaminates in such high concentrations that Bentonite Slurry Walls will not hold up to them so the only option is the HDPE poly wall to create an impervious, continuous, containment wall.

- Trench Depths:0-40′ deep (deeper with grading)

- Trench Width:12″- 48″ wide

- Speed:Typically 200-300 linear feet per day.

- Saftey:Continuous backfill elimates dangerous open trenches

- Results:Superior performace in low-permeability soils.

|

|

© 2012 Dewind. All Rights Reserved.Designed by Planted Meida