Company History

Company History

Greg and Becky DeWind started their business in the construction dewatering business over thirty years ago. Today, their business has expanded into a full service shop specializing in underground problem solving through the development of the DeWind One-Pass Trenchers, the world’s most capable and deepest reaching trenchers.

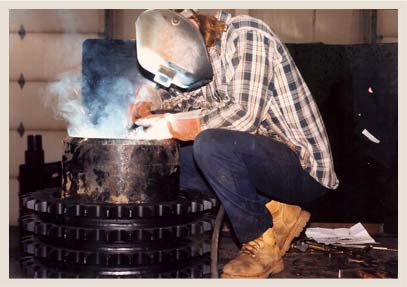

Greg DeWind is recognized as an industry leader in the engineering and manufacturing world. Working out of several fabrication shops in Holland Michigan, DeWind employ a large team of highly skilled machinists, welders, mechanics and operators that build and maintain the inventory of custom machines including: Trenchers, All Terrain Construction Vehicles, Custom Drill Rigs, High Pressure Jet Rigs, and other custom problem solving equipment used in the construction dewatering and deep trenching industries.

DeWind’s ability to solve complex engineering problems across a diverse spectrum of conditions has been the driving force behind their success. For three decades, their pursuit of innovation has resulted in improved techniques while consistently delivering reliability, every time.

Every DeWind One-Pass Trencher is custom built and has phenomenal depth capability, power, dependability and is safe. The meticulous engineering of the DeWind One-Pass Trenchers is a cost-savings when performing deep trenching and is environmentally friendly.

To learn more about the history of DeWind One-Pass Trenching and Dewatering call 616-875-7580 or send message LINK TO CONTACT PAGE HERE

Technology

Technology

DeWind’s One-Pass Trencher is built using unique and revolutionary technology. This trench allows the installation of deep containment walls, groundwater and product recovery trenches, permeable reactive barriers, soil vapor or injection trenches to be installed underground, under the water table and IN A SINGLE PASS. There is no need to pump, treat, shore, or dig mass excavations! It also eliminates the need for dangerous deep and wide-open excavations. The installations are fast, surgically precise, and can be completed on the most challenging job sites such as between structures, under overpasses; on levees- anywhere conventional excavation equipment would be inconceivable.

The DeWind One-Pass Trenchers and attachments are custom designed. Each trencher is a track-mounted machine that has a cutting boom resembling a large chain saw. Horsepower ranges from 750hp to 3,500hp, making them the deepest, most powerful unconsolidated soils trenchers available in the world.

All trenchers have interchangeable cutting booms and can cut a nominal 12, 24, 36 and 48 inch wide trench. Trench depths vary depending on the size. Trencher and systems installed from 0 to 50 feet deep for backfilled trenches to In-situ mixed soil bentonite walls can be installed up to 125 feet. Dual laser-guided systems ensure a precise, automatic depth control of the cutting boom during installations and GPS tracking can map the system as it is being installed.

The DeWind One-Pass Trenchers allow engineers to design solutions that can be installed in a single pass using far less equipment and in a shorter amount of time. The technology improves safety by eliminating the need for open pit excavations.

Commitment to Safety

Commitment to Safety

DeWind’s unwavering commitment to safety is accomplished by extensive training. All DeWind Trencher Operators are initially trained as mechanics to ensure a solid understanding of welding, metal fabrication, electrical and hydraulic systems. This level of training promotes a safe work environment by building a comprehensive understanding of the equipment and its abilities.

DeWind offers crews fully trained for work on hazardous waste sites, and all operators and laborers are 40-hour OSHA trained with a current 8-hour refresher. We will operate under a Health and Safety Plan that is in compliance with 29 CFR 1910.120 and other OSHA requirements.

Environmental Services

Environmental Services

DeWind offers a number of Environmental Construction Services related to the clean up, protection, and improvement of the environment. The DeWind Team is Hazmat trained and their proprietary technologies result in easy systems installations underground, under the water table IN A SINGLE PASS without the need to pump, treat, shore, or dig mass excavations. DeWind’s environmental services result in quicker clean ups, and a significant reduction in job site spoils. DeWind’s Environmental Services include:

- Ground Water and Product Recovery Trenches

- In-Situ Mixed Soil Bentonite Slurry Walls

- Permeable Reactive Barriers

- Soil Vapor Extraction Trenches

- Injection Trenches.

- Leachate Collection

- HDPE Barrier Walls

- Permeable Reactive Barrier

Civil Services

Civil Services

In the 30 years DeWind has been in the construction business they have developed an impressive list of services. Their proprietary machinery and methodology has been fine-tuned over decades, and their one-pass technology gives them unmatched precision, and speed during installations. All installations are executed under the static water table in one pass, eliminating the need for open excavations. DeWind’s Civil Services include:

- Underground Alluvial Water Storage Reservoir Containment Walls

- In-Situ Soil/Cement Bentonite walls.

- Foundation Stabilization.

- Large Diameter HDPE Pipe Installations

- Direct Bury Of Ductile Iron and PVC Pipe.

- Cement Footing Foundations and “Formless Wall” Installs

- Full-Service Construction Dewatering Services

- Large Volume Water Supply Systems for Irrigation.

- Erosion Control System for Slope and Tailing Stability.

- Relief Trenches AND MORE.

© 2012 Dewind. All Rights Reserved.Designed by Planted Meida